Engineering

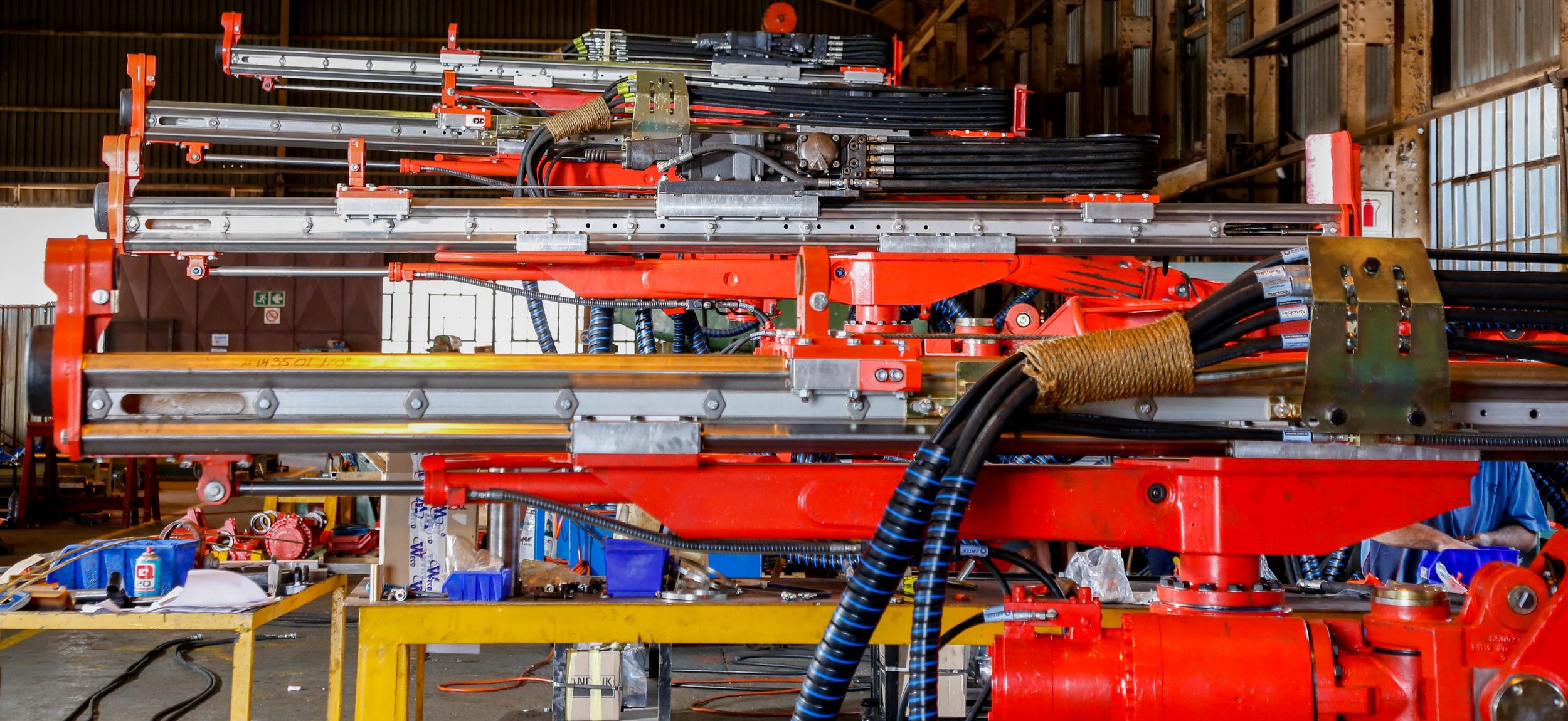

Drill Rig Booms

We specialise in Drill Rig Boom Refurbishments and Manufacturing, as well as specific maintenance programs established to suit customer needs in underground drilling operations.

⌄

end-to-end Refurbishment Process

All the parts we receive are professionally Washed, Stripped and Assessed by our team to determine the best possible solution for our clients. Based on the condition, the parts will either be sent for machining or discontinued and re-fabricated.

Our team follows strict Quality Assessment processes throughout the entire project to insure that all Quality Management Systems are ISO 9001-2015 ASR.

Sandvik Drill Rig Booms

Eventspec is fully capable of refurbishing and building Sandvik DS211, DS411, DD421, DD420, DS311, DD321 and DD210L Drill Rig Booms.

full capacity workshops

Our 3500m2 + 1200m2 workshops has dedicated Machining Equipment, namely CNC, Conventional Lathes and Milling Machines, as well as full capacity for Fabrication and Final Assembly Facilities for Underground Drill Rig Booms.

Forming part of the workshop is our Hydraulic Assembly Room where we overhaul components. Using our hydraulic test bench, our team diligently inspects and tests each cylinder to insure proper functionality within specific operation parameters.

Epiroc Drill Rig Booms

Eventspec is fully capable of refurbishing and building Epiroc 235 Boltec, MC Boltec, Simba M6C, Simba S7D and 282 Drill Rig Booms.